This system is the most durable and the heavy-duty system. The special industrial epoxy KaroTEK Past Plus used in joint filling and adhesive is combined and cured at the same time. Thus, industrial ceramics are resistant to all kinds of high temperature acidic and caustic discharges for a long time and there is no rupture in areas where there is constant expansion and contraction due to temperature change.

Place of use: dairy and milk product facilities, all kinds of beverage factories, cold rooms, places with oven and cooking areas, etc.

Materials Used

- Ceramic: Industrial, 200X200 14 mm and/or hexagonal 15mm/18 mm thickness, R10/R11/R12 V04-06 non-slip surface classes, capable of withstanding high level load (Max > 500 kg /mm2 ), water absorption rate less than 0.5%, stain-free, resistant to all kinds of acidic and caustic chemical solutions, non-bacteria forming, 1.Class porcelain ceramic.

- Epoxy adhesive and joint material: Industrial, European origin, water absorption less than 0.5%, non-bacteria forming, resistant to all kinds of acidic and caustic chemical solution, epoxy joint and adhesive material.

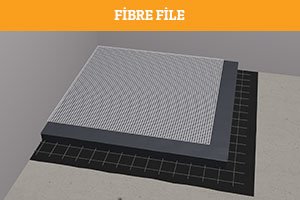

- Screed material: Cem II 32.5 R / Cem I 42.5 R Portland Cement, washed filtered sand, special curing retardant screed additive, Q 106/131 steel mesh.